Blade Flyer

Remotely Controlled Model - Page 8

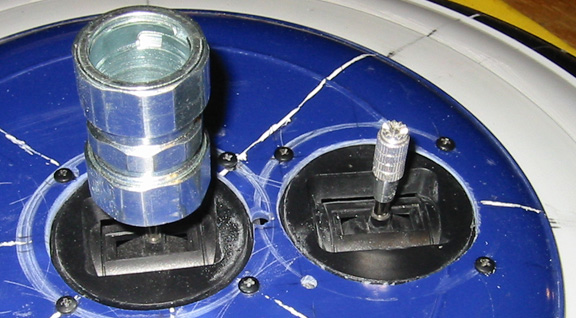

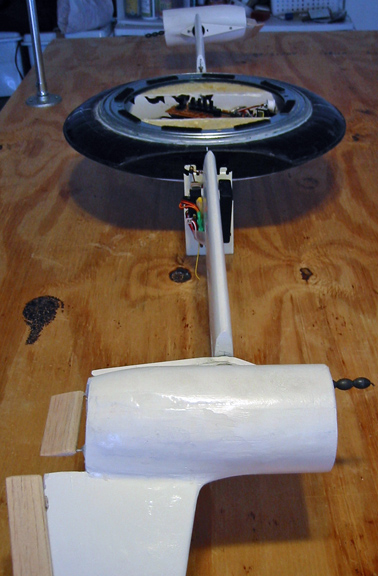

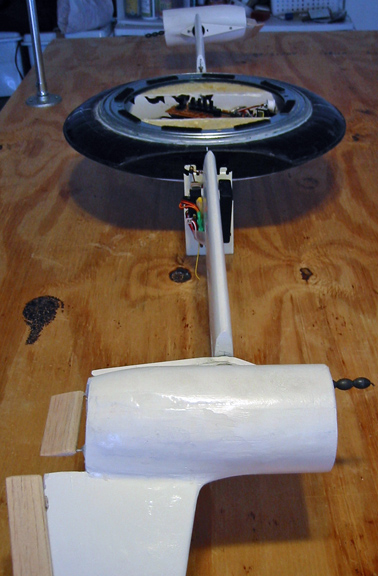

Disassembled the transmitter, and installed the

pitch-roll joystick at the center of the bottom of the vehicle, and the

motor control and yaw control adjacent to it. Bolted pipe coupler to

the pitch-roll joystick.

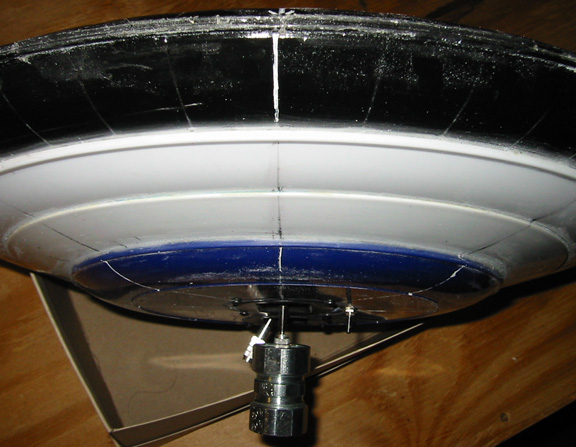

Moved the power switch to the side of the pitch-roll gimbal. Having the

weight of the entire vehicle supported on the joy stick is a major

concern. That's why the secondary support from the top.

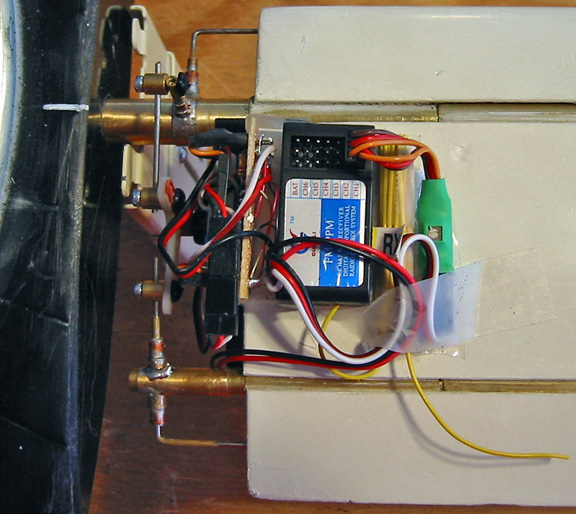

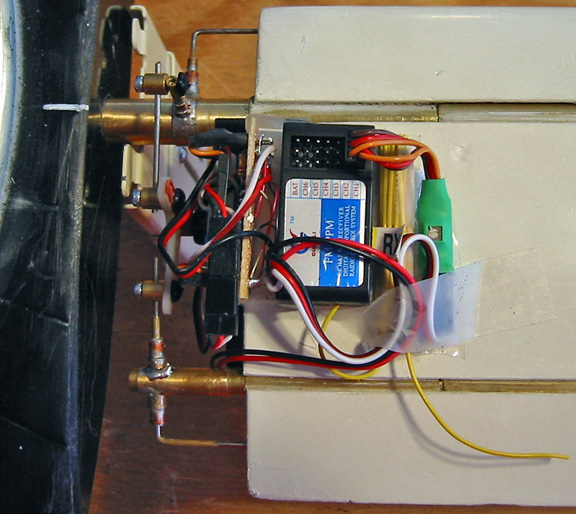

Moved the roller servo and receiver more to the aft.

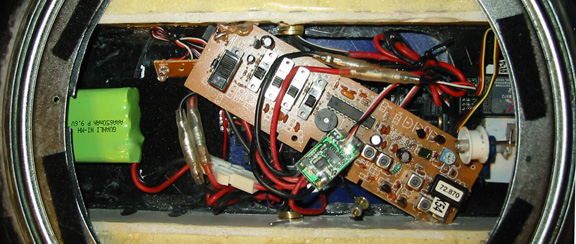

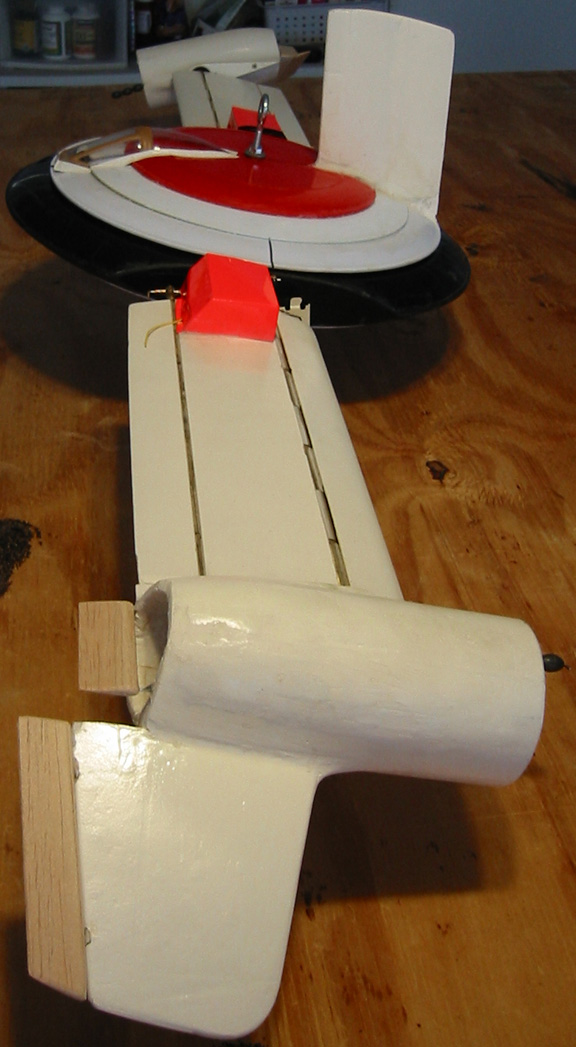

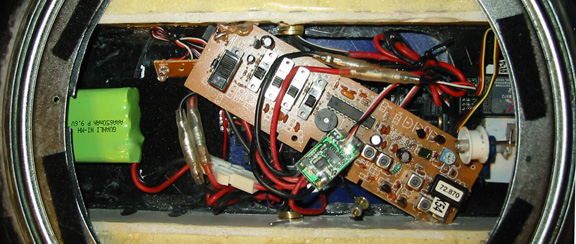

Installed the transmitter circuit board. Moved the

battery forward to balance the vehicle in pitch.

During the test, the power is enabled with the switch, and the

throttle is advanced to maximum. When the rotational velocity is high

enough for the roller counter-weight to keep the roller down, the yaw

control will be actuated with a stick to release the roller. The truck

accelerates until the translation velocity exceeds the rotation

velocity, and the engines and blades transition into the conventional

flight configuration. During the last few rotations, the roller weight

cause the roller to engage the slot in the top, so the vertical

stabilizer on the top stops the rotation, and maintains the vehicle

pointed into the translation air flow in conventional the flight

configuration.

Message to Dionysus

Design for later use here:

It

takes people a while to get their head around this concept. The

lifting surfaces are like helicopter blades during vertical flight and

wings during conventional flight.

INTRODUCTION

Google Air

Hogs Switchblade RC Plane to see a Canadian design that could be

construed to violate the Blade Flyer patent. It is a

symmetric

airfoil design that uses a spring to flip one blade relative to the

other once per flight. It must be manually reset. Its blades

are

directly connected to each other on a common axle. Its

engines

are fixed on each blade/wing.

The following text explains the photos and videos at BladeFlyer.com:

The

Blade Flyer is variable camber and uses translation air flow to flip

the blades into wings, so it automatically transitions between flight

modes as a function of its translation velocity. Each blade

is

independently connected to a common hub by way of an axle. The

engines are on the wing tips and freely pivot about their center of

gravity. For maximum efficiency, a vane on the engine keeps

the

engine pointed into the dominant air flow, regardless of whether it is

due to rotation or translation.

The engines begin flipping as

their translation air speed exceeds their rotation air speed. When the translation velocity of the retreating blade exceeds its

rotation speed, it flips. The engine and blade flipping slows

the

rotation to zero, and the vehicle achieves a conventional flight

configuration. A torque motor on the hub axle or a vertical

stabilizer on the hub engages to maintain the conventional flight

configuration. These are disengaged and the vehicle pitched

up or

otherwise slowed to reverse the process, and revert to vertical flight

configuration.

To avoid roll during transition, the dihedral on

the engine vane always causes the engine on the retreating blade to

flip with its thrust vector down to compensate for the reduced lift the

retreating blade relative to the advancing blade.

The blade/wing

airfoils are symmetric. Articulating leading and trailing

edges

provide camber to improve lift efficiency. A single servo in

each

blade actuates both the leading and trailing edges. Each

blade

has its own receiver and battery pack.

Each blade pivots on an

axle along the quarter chord (center of lift) of the blade. A

photo detector on each blade reflects its light off the blade

axle. Electrical tape on half of the circumference of the

axle

absorbs the light, and deactivates the photodetector as the blade

rotates about its axle. When again exposed to the shinny

brass of

the axle as the blade continues to rotate on the axle, the

photodetector reactivates.

By way of other circuitry, the

photodetector accordingly includes your servo reverser and glitch

reducer in the circuit between the receiver and servo, or excludes the

servo reverser and glitch reducer from the circuit between the receiver

and servo. This assures that the blade camber is always

producing

positive lift, regardless of the orientation of the blade (flipped or

not).

I need only demonstrate to DARPA that the Blade Flyer does

not lose lift during transition from vertical to conventional flight

mode and back. The wind tunnel I built for testing the

components

was under-sized to test the entire model, so I will mount the test

platform and model on a truck, drive it along our straight and flat

deserted desert roads, and video-tape a scale and the model during

translation at about 35 mph.

The model must be relatively free

to roll and demonstrate that it can maintain level flight during this

test, so I mounted the transmitter pitch-roll joystick gimbal inverted

in the center of the bottom of the hub. I secured the stick

to a

to bearing in a pedestal on the test stand such that a roll of the

model causes a roll command from the gimbal that increases the camber

on the low blade and decreases the camber on the high blade to correct

the roll of the vehicle during rotation in vertical flight mode or

during translation in conventional flight mode.

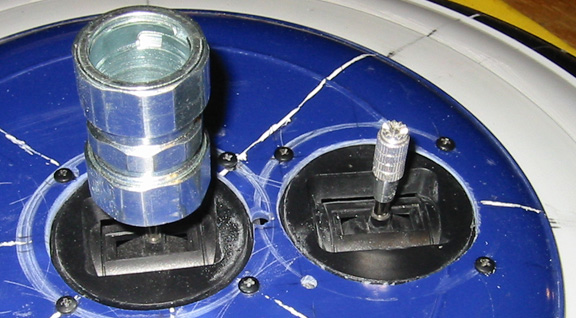

I mounted the

yaw-thrust joystick gimbal inverted in the bottom of the hub as

well. I mounted the transmitter, battery, engine control and

a

receiver in the middle of the hub. The engine control wires

thread through each axle, and connect to the male side of telephone

cable detangler in the end of the axle. The engine nacelles

mount

to bearings on the end of the axle such that the female side of the

telephone cable detangler in the nacelle connects to the male side to

provide power to the freely pivoting engines.

I mounted

the yaw servo in the middle of the hub such that it holds the axle of

the roller horizontal (in the plane of the hub) in counteraction to

weights on the other end of the roller axle, which pivots on a fulcrum

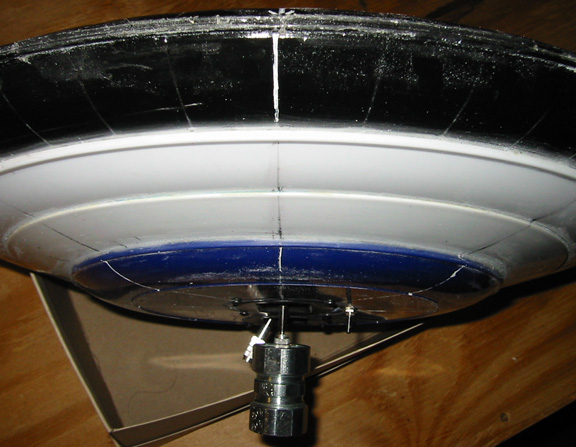

near its middle. The upper third of the hub freely rotates on

a

ring bearing such that its vertical stabilizer is free to orientate the

upper hub into the wind caused by translation. The upper hub

has

a rectangular slot in it that is slightly larger than the roller.

I

mounted a master switch in the bottom of the hub to interrupt the

circuit between the battery and the transmitter, yaw servo and engine

control, so the transmitter switch could be enabled and engine thrust

could be set before the test with the master switch off to preclude

anything from happening before I'm ready to start the test by enabling

the battery packs on each blade and the master switch on the hub.

The

blades and engines will be manually set in their vertical flight

orientation, and the engine thrust will be set to maximum before the

test.

Movement of the yaw stick by me in the back of the

truck with a pole after maximum rotation velocity is achieved will

release the weighted roller in the hub. Centrifugal force

will

keep the roller from engaging a slot in the upper hub. As the

rotation of the hub declines during transition, the roller will raise

to engage the slot in the top section of the hub. The

vertical

stabilizer on the top section of the hub will then stabilize the

vehicle in conventional flight mode.

YOU (Dionysus

Design)

The servos on

both blades must be signaled to cause some camber and some

corresponding lift to unweight the pedestal scale on the test stand

during vertical flight mode. I can do this with the pitch

potentiometer on the pitch-roll joystick by removing it from the

gimbal, and manually setting its position before the test.

The

servo on each blade must receive this fixed pitch signal as well as any

roll signal caused by the roll of the model on its pedestal. Hence the

pitch channel and roll channel on the receiver on each blade

must be mixed on its way to the photodetector circuit that supplies the

servo with its signal.

Is your V-Tail mixer appropriate for this purpose? If not,

what is?

Working mixers finally received and installed.

Adjusting battery position to nutralize pitch.

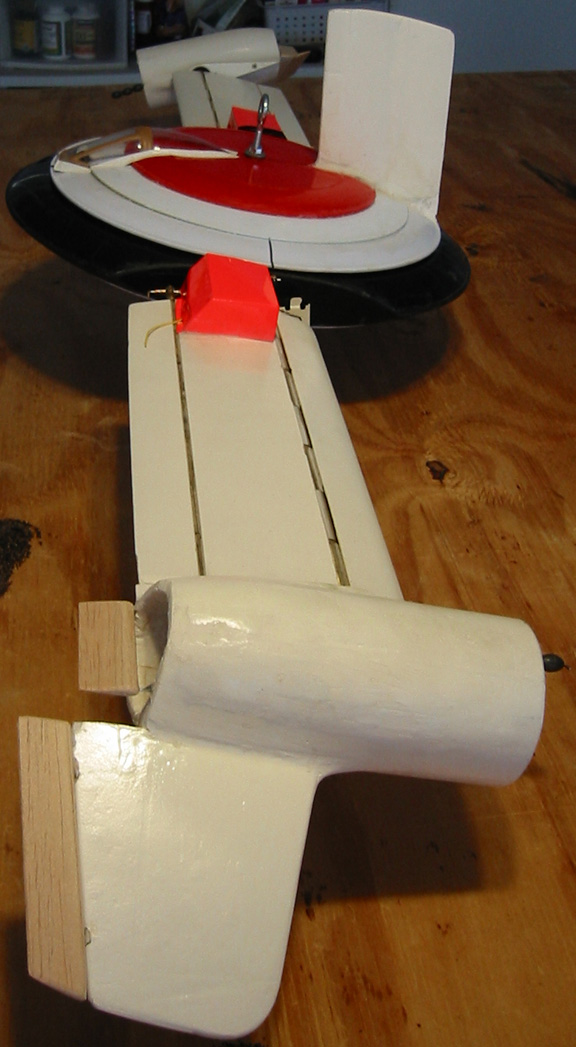

Covers for receiver and other electronics.

The

hub power switch and power LEDs cleared the original support, but a new

start-up support that clears the thrust and upper hub release joy stick

in its zero thrust position was required.

Safety support.

Full test assembly with model weight scale and air velocity meter on slide.

View from video camera showing support release string attached to pin in pedistal.

Contact: Bill Holmes via email or 661-305-9465

| Home

| Wind Tunnel | Model 0 | Model 1 | Model 2

| Model 3 | Model 4 | Model 5 | Model 6

| Model 7 | Model 8 | Model 9

| Model 10 | Captive |